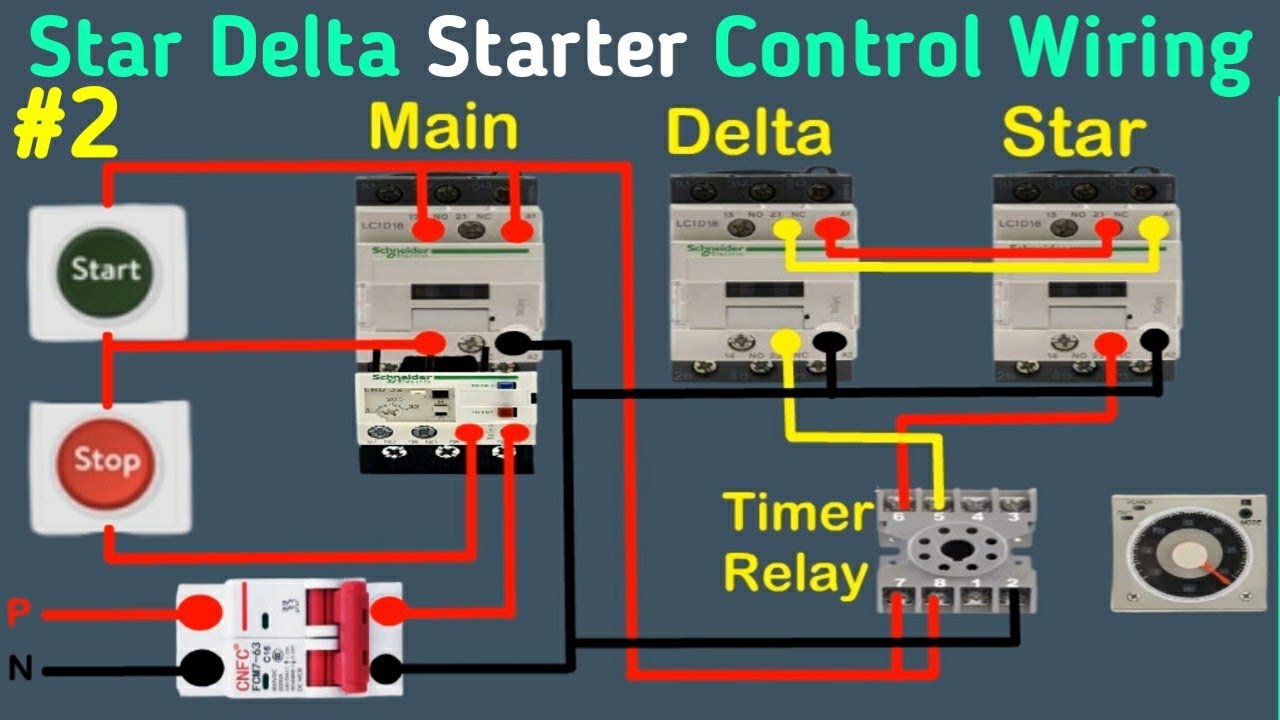

Star Delta Interlocking | Timer Relay Connection | Contactor Switching Star Delta

Starting & Controlling of 3-Phase Motor using Semi-Automatic Star-Delta Starter Without Timer

Electric motors are essential components in various industrial applications and play a vital role in powering machines, pumps, compressors, and other equipment. However, when it comes to starting large motors, the initial inrush current can be significantly high, leading to voltage drops and potential damage to the motor windings. That’s why do we need a PLC, VFD, or a motor starter such as a Star-Delta Starter.

To overcome this challenge, engineers have developed various motor starting methods, and one such method is the “Star-Delta Starter.” As we have explained the automatic star-delta starter using a timer in the previous post, In this article, we will explore the power and control diagram, working principle and applications of semiautomatic or manual star-delta starter without using a timer.

Introduction to Star-Delta Starter

A star-delta starter is a widely used method for starting three-phase induction motors. It allows for a gradual reduction of the starting current, reducing the impact on the power supply and the motor itself. Typically, an automatic star-delta starter uses a time delay relay to switch between the star and delta connections of the motor windings. However, in some cases, the use of a timer may not be necessary or practical, especially in applications where simplicity and cost-effectiveness are crucial.

Working Principle of Star-Delta Starter without Timer

The star-delta starter without timer follows a basic principle: the motor starts in a star configuration, and after a predefined time, it switches to the delta configuration. These methods are used when a time delay timer is faulty or not available during the emergency operation of large motors.

Unlike the conventional star-delta starter, this method does not use a time delay relay. Instead, it relies on manual control for the switching process e.g. Using push button switches for manual operation for transferring the mains connection from Star to Delta.

Star Connection

During the starting process, the motor windings are initially connected in a star (Y) configuration. In the star connection, each winding receives the full line voltage (VL) across them. This configuration allows the motor to draw reduced current compared to a direct-on-line start.

Delta Connection

After a specific period (usually a few seconds) of running in star mode, the motor windings are switched to a delta (Δ) configuration. In the delta connection, each winding receives the line voltage divided by the square root of 3 (√3) across them. This results in an increase in the current but provides higher torque, allowing the motor to reach its full speed.

Challenges of Multi-Button Motor Control

Controlling a 3-phase motor from more than two buttons introduces several challenges:

Interlocking: To prevent conflicting commands from multiple buttons, an interlocking mechanism must be in place. This ensures that only one command (start or stop) is executed at a time. This prevents damage to the motor or machinery.

Complexity: As the number of control buttons increases, so does the complexity of the control system. Design and wiring can become intricate.

Distance: The control stations may be located far apart, making it impractical to run wires directly from each station to the motor starter.

Safety: Emergency stop functionality must be available at all control points to ensure the safety of personnel and equipment.

Reliability: The control system must be reliable, ensuring that a command to start or stop the motor is always executed correctly.

Working of the Motor Control Circuit

Let’s see how the control circuit of a 3-phase motor can be operated from more than two locations using pushbuttons.

Multi-Button Control Stations

One straightforward approach is to install multi-button control stations at various locations within the facility. These stations are wired directly to the motor starter’s control circuit. Each station can include multiple buttons for different functions, such as start, stop, forward, reverse, and speed control.

In the above circuit, three ON (NO) and OFF (NC) pushbuttons are used. (Additional ON/OFF buttons may be added if you want to control the motor from even more places. An additional emergency stop buttons may be added for extra protection.)

As shown, when the operator presses the ON 1 switch, the holding circuit is completed since all the OFF pushbuttons are normally closed (NC). Consequently, the contactor energizes, and the motor starts running.

Star Delta Interlocking | Timer Relay Connection | Contactor Switching Star Delta

Starting & Controlling of 3-Phase Motor using Semi-Automatic Star-Delta Starter Without Timer

Electric motors are essential components in various industrial applications and play a vital role in powering machines, pumps, compressors, and other equipment. However, when it comes to starting large motors, the initial inrush current can be significantly high, leading to voltage drops and potential damage to the motor windings. That’s why do we need a PLC, VFD, or a motor starter such as a Star-Delta Starter.

To overcome this challenge, engineers have developed various motor starting methods, and one such method is the “Star-Delta Starter.” As we have explained the automatic star-delta starter using a timer in the previous post, In this article, we will explore the power and control diagram, working principle and applications of semiautomatic or manual star-delta starter without using a timer.

Introduction to Star-Delta Starter

A star-delta starter is a widely used method for starting three-phase induction motors. It allows for a gradual reduction of the starting current, reducing the impact on the power supply and the motor itself. Typically, an automatic star-delta starter uses a time delay relay to switch between the star and delta connections of the motor windings. However, in some cases, the use of a timer may not be necessary or practical, especially in applications where simplicity and cost-effectiveness are crucial.

Working Principle of Star-Delta Starter without Timer

The star-delta starter without timer follows a basic principle: the motor starts in a star configuration, and after a predefined time, it switches to the delta configuration. These methods are used when a time delay timer is faulty or not available during the emergency operation of large motors.

Unlike the conventional star-delta starter, this method does not use a time delay relay. Instead, it relies on manual control for the switching process e.g. Using push button switches for manual operation for transferring the mains connection from Star to Delta.

Star Connection

During the starting process, the motor windings are initially connected in a star (Y) configuration. In the star connection, each winding receives the full line voltage (VL) across them. This configuration allows the motor to draw reduced current compared to a direct-on-line start.

Delta Connection

After a specific period (usually a few seconds) of running in star mode, the motor windings are switched to a delta (Δ) configuration. In the delta connection, each winding receives the line voltage divided by the square root of 3 (√3) across them. This results in an increase in the current but provides higher torque, allowing the motor to reach its full speed.

Challenges of Multi-Button Motor Control

Controlling a 3-phase motor from more than two buttons introduces several challenges:

Interlocking: To prevent conflicting commands from multiple buttons, an interlocking mechanism must be in place. This ensures that only one command (start or stop) is executed at a time. This prevents damage to the motor or machinery.

Complexity: As the number of control buttons increases, so does the complexity of the control system. Design and wiring can become intricate.

Distance: The control stations may be located far apart, making it impractical to run wires directly from each station to the motor starter.

Safety: Emergency stop functionality must be available at all control points to ensure the safety of personnel and equipment.

Reliability: The control system must be reliable, ensuring that a command to start or stop the motor is always executed correctly.

Working of the Motor Control Circuit

Let’s see how the control circuit of a 3-phase motor can be operated from more than two locations using pushbuttons.

Multi-Button Control Stations

One straightforward approach is to install multi-button control stations at various locations within the facility. These stations are wired directly to the motor starter’s control circuit. Each station can include multiple buttons for different functions, such as start, stop, forward, reverse, and speed control.

In the above circuit, three ON (NO) and OFF (NC) pushbuttons are used. (Additional ON/OFF buttons may be added if you want to control the motor from even more places. An additional emergency stop buttons may be added for extra protection.)

As shown, when the operator presses the ON 1 switch, the holding circuit is completed since all the OFF pushbuttons are normally closed (NC). Consequently, the contactor energizes, and the motor starts running.

No comments:

Post a Comment