Voltage Quadrupler Circuit with Only Capacitor and Diode

Need more voltage than your supply can deliver? This is the device to build.

Based upon the Villard doubler, cascaded in multiple stages, this circuit will multiply a small AC voltage into a huge potential.

With a 6000 VAC Oil Burner Transformer and just three stages, you can multiply the potential from 6000 to 51,000 VDC!

Also, the higher the voltage ratings on your components, the higher the input voltage can be and therefore, more bang for your buck.

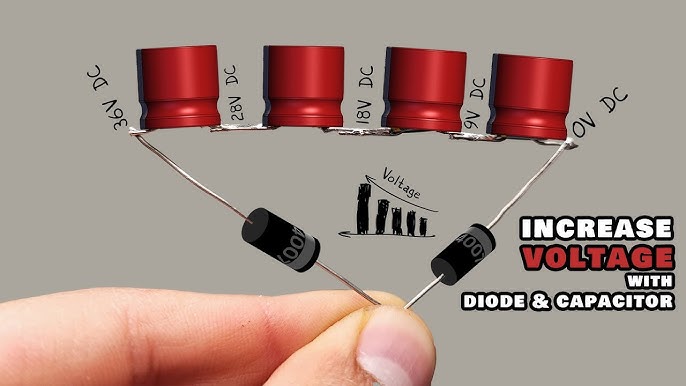

One side benefit of a stack like this is you can tap off various voltages from stage to stage. In this example, three outputs of 17000, 34000, and 51000 volts are available. Nice!

Each stage of this multiplier is a doubler circuit and is made up of (2) Capacitors and (2) Diodes.

On the positive half-cycle of the input, the capacitors charge in parallel to the peak value of the voltage presented through the forward biased diode. The other diode is reversed biased. Each cap charges to 8484 peak volts.

On the negative half-cycle of the input, the forward biased diode becomes reversed biased while the reversed biased diode becomes forward biased. This effectively connects the capacitors in series allowing them to discharge into the load at the output. The result is a doubled voltage presented to the load or 16968 peak volts.

Each connected stage adds its potential to the total output.

To calculate the expected voltage at the output with a given input and number of stages, plug the numbers into this formula:

Eout = (2 x Ein) x S x 1.414

Eout is the Output Voltage, Ein is the Input Voltage, and S is the number of stages in your design. I used a 6,000 VAC Oil Burner Transformer for my input and built 3 stages.

Eout = (2 x 6000) x 3 x 1.414

Eout = 12000 x 3 x 1.414

Eout = 36000 x 1.414

Eout = 50,904 volts

All of the critical parts are available on eBay. Here's what you will need:

(6) 470 picofarad, 20KV Ceramic Doorknob Capacitors.

(6) HV03-12 12KV PIV High Voltage Diodes.

(7) Brass or copper wiring posts (homemade).

(8) 8-32 x 1 in. brass screws.

A length of 50KV High Voltage wire for the output.

A length of 20KV High Voltage wire for the input.

A length of 12ga. Stranded wire for ground.

(3) #8 Wire lugs.

(1) Ziploc Food Storage Container is large enough to hold the multiplier (not a bag).

(1) qt. Mineral Oil.

RTV Silicon Rubber Sealant.

NOTE: Only the voltage rating on the components is critical.

The higher the rating, the higher the input voltage can be, resulting in a higher output voltage. The input limit on this design is 10KV (with safety margin built in). Ignition wire or coax cable with the shield removed may be substituted for high voltage wiring if need be.

This step isn't rocket science, just common sense building techniques. Just copy the design shown with the binding studs added.

Start by cutting (7) pieces of 16 guage brass or copper wire two inches long. Bend each piece around a drill bit and shape with a loop at one end.

Next, cut the heads off four of the screws to make the studs that join the capacitors together.

Screw a stud into one of the caps. Place a binding post over the stud and screw on another capacitor. Screw in another stud, place a binding post over it and screw on the last capacitor.

Repeat the previous step to create two stacks of three caps each.

Lay the two stacks side by side with the binding posts pointing up.

Cut the remaining four screws to 1/2 inch long.

Attach binding posts to the right side end of each stack using a screw.

Attach a binding post to the left end of the bottom stack using a screw.

Attach the diodes as shown and solder them to the binding posts.

Cut off any excess binding post tops and file them flush to the soldered diodes. No sharp edge here or you will get an unwelcomed breakover which could ruin your project.

Attach the wires with lugs. Tighten the screws and make sure the entire assembly is tight.

Now that the multilpier is finished, we need to encase it in oil.

With the lid still on the Ziploc container, punch three holes in the lid at the approximate locations where the leads will exit it. Remove the lid from the container and set it aside.

Slowly fill the empty, clean Ziploc container half way with mineral oil without creating any bubbles in the oil. Oil good! Air bad!

Hold the multiplier by its leads and slowly lower it into the oil bath.

Continue holding the leads with one hand and slowly pour more oil over the multiplier until it has at least a 1/2 inch covering and about 1/2 inch head space between the oil and the lid.

Now pass the leads one at a time through the holes in the lid then work the lid down onto the container while holding the leads. Do not get oil on the leads at the lid level or the sealant will not stick or seal the wires. Snap the lid onto the container.

Finally, seal the leads and if you like, the lid to the container with the RTV sealant and set the project aside for 24 hours until the RTV cured.

This multiplier is part of a 0 to 50KV adjustable High Voltage Power Supply capable of sourcing 20 milliamps of current.

An instructable on building the supply is my next project, so hold on!

SAFETY WARNINGS AND PROCEDURES

This device produces LETHAL CURRENTS at HIGH VOLTAGE. The output of this device WILL KILL YOU if you do not follow standard common sense safety procedures.

Safety Precautions and Procedures

1. Wear safety goggles or glasses, rubber safety gloves, and stand on a rubber safety mat when powering or using this device.

2. GROUND the output of this device after powering it off. It can retain a lethal voltage for several minutes after powering down.

3. DO NOT TOUCH THE DEVICE AT ANY TIME DURING OPERATION.

4. Do not allow others who are not familiar with high voltage devices to touch or use this device without proper supervision.

5. Do not operate this device alone! Have an emergency person available when performing your experiments who is familiar with proper rescue procedures.

DISCLAIMER

By building and operating this device, you acknowledge that you understand the dangers improper operation can pose and you accept all risks associated with the operation of this device.

You also acknowledge that I am neither nor will be responsible for any death or dismemberment by this device whatsoever and that you assume all risks by the use of this device.

Voltage Quadrupler Circuit with Only Capacitor and Diode

Need more voltage than your supply can deliver? This is the device to build.

Based upon the Villard doubler, cascaded in multiple stages, this circuit will multiply a small AC voltage into a huge potential.

With a 6000 VAC Oil Burner Transformer and just three stages, you can multiply the potential from 6000 to 51,000 VDC!

Also, the higher the voltage ratings on your components, the higher the input voltage can be and therefore, more bang for your buck.

One side benefit of a stack like this is you can tap off various voltages from stage to stage. In this example, three outputs of 17000, 34000, and 51000 volts are available. Nice!

Each stage of this multiplier is a doubler circuit and is made up of (2) Capacitors and (2) Diodes.

On the positive half-cycle of the input, the capacitors charge in parallel to the peak value of the voltage presented through the forward biased diode. The other diode is reversed biased. Each cap charges to 8484 peak volts.

On the negative half-cycle of the input, the forward biased diode becomes reversed biased while the reversed biased diode becomes forward biased. This effectively connects the capacitors in series allowing them to discharge into the load at the output. The result is a doubled voltage presented to the load or 16968 peak volts.

Each connected stage adds its potential to the total output.

To calculate the expected voltage at the output with a given input and number of stages, plug the numbers into this formula:

Eout = (2 x Ein) x S x 1.414

Eout is the Output Voltage, Ein is the Input Voltage, and S is the number of stages in your design. I used a 6,000 VAC Oil Burner Transformer for my input and built 3 stages.

Eout = (2 x 6000) x 3 x 1.414

Eout = 12000 x 3 x 1.414

Eout = 36000 x 1.414

Eout = 50,904 volts

All of the critical parts are available on eBay. Here's what you will need:

(6) 470 picofarad, 20KV Ceramic Doorknob Capacitors.

(6) HV03-12 12KV PIV High Voltage Diodes.

(7) Brass or copper wiring posts (homemade).

(8) 8-32 x 1 in. brass screws.

A length of 50KV High Voltage wire for the output.

A length of 20KV High Voltage wire for the input.

A length of 12ga. Stranded wire for ground.

(3) #8 Wire lugs.

(1) Ziploc Food Storage Container is large enough to hold the multiplier (not a bag).

(1) qt. Mineral Oil.

RTV Silicon Rubber Sealant.

NOTE: Only the voltage rating on the components is critical.

The higher the rating, the higher the input voltage can be, resulting in a higher output voltage. The input limit on this design is 10KV (with safety margin built in). Ignition wire or coax cable with the shield removed may be substituted for high voltage wiring if need be.

This step isn't rocket science, just common sense building techniques. Just copy the design shown with the binding studs added.

Start by cutting (7) pieces of 16 guage brass or copper wire two inches long. Bend each piece around a drill bit and shape with a loop at one end.

Next, cut the heads off four of the screws to make the studs that join the capacitors together.

Screw a stud into one of the caps. Place a binding post over the stud and screw on another capacitor. Screw in another stud, place a binding post over it and screw on the last capacitor.

Repeat the previous step to create two stacks of three caps each.

Lay the two stacks side by side with the binding posts pointing up.

Cut the remaining four screws to 1/2 inch long.

Attach binding posts to the right side end of each stack using a screw.

Attach a binding post to the left end of the bottom stack using a screw.

Attach the diodes as shown and solder them to the binding posts.

Cut off any excess binding post tops and file them flush to the soldered diodes. No sharp edge here or you will get an unwelcomed breakover which could ruin your project.

Attach the wires with lugs. Tighten the screws and make sure the entire assembly is tight.

Now that the multilpier is finished, we need to encase it in oil.

With the lid still on the Ziploc container, punch three holes in the lid at the approximate locations where the leads will exit it. Remove the lid from the container and set it aside.

Slowly fill the empty, clean Ziploc container half way with mineral oil without creating any bubbles in the oil. Oil good! Air bad!

Hold the multiplier by its leads and slowly lower it into the oil bath.

Continue holding the leads with one hand and slowly pour more oil over the multiplier until it has at least a 1/2 inch covering and about 1/2 inch head space between the oil and the lid.

Now pass the leads one at a time through the holes in the lid then work the lid down onto the container while holding the leads. Do not get oil on the leads at the lid level or the sealant will not stick or seal the wires. Snap the lid onto the container.

Finally, seal the leads and if you like, the lid to the container with the RTV sealant and set the project aside for 24 hours until the RTV cured.

This multiplier is part of a 0 to 50KV adjustable High Voltage Power Supply capable of sourcing 20 milliamps of current.

An instructable on building the supply is my next project, so hold on!

SAFETY WARNINGS AND PROCEDURES

This device produces LETHAL CURRENTS at HIGH VOLTAGE. The output of this device WILL KILL YOU if you do not follow standard common sense safety procedures.

Safety Precautions and Procedures

1. Wear safety goggles or glasses, rubber safety gloves, and stand on a rubber safety mat when powering or using this device.

2. GROUND the output of this device after powering it off. It can retain a lethal voltage for several minutes after powering down.

3. DO NOT TOUCH THE DEVICE AT ANY TIME DURING OPERATION.

4. Do not allow others who are not familiar with high voltage devices to touch or use this device without proper supervision.

5. Do not operate this device alone! Have an emergency person available when performing your experiments who is familiar with proper rescue procedures.

DISCLAIMER

By building and operating this device, you acknowledge that you understand the dangers improper operation can pose and you accept all risks associated with the operation of this device.

You also acknowledge that I am neither nor will be responsible for any death or dismemberment by this device whatsoever and that you assume all risks by the use of this device.

No comments:

Post a Comment