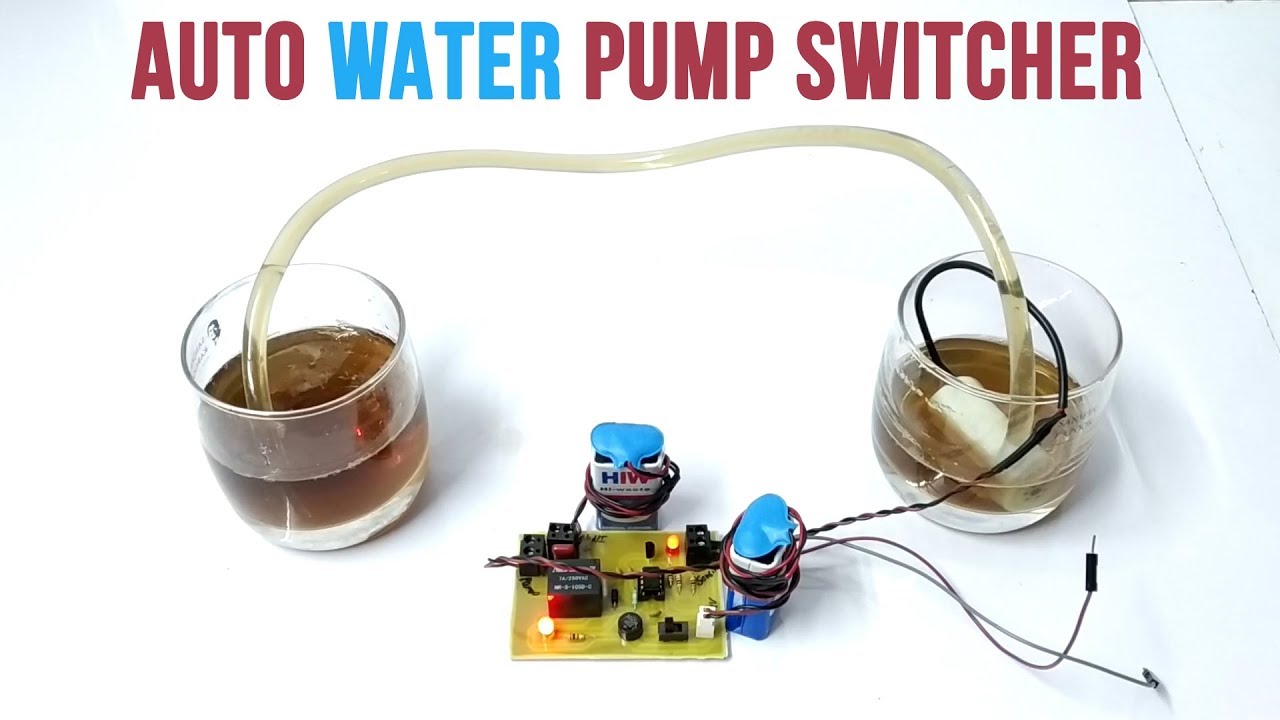

Ne555 automatic water pump control circuit

Hii Everyone here we are going to learn about saving the water efficiently. So go through the steps and the Sentences carefully. Water tank overflow is a common problem which leads to the wastage of water. Although there are many solutions to it like ball valves which automatically stop the water flow once the tank gets full. The water level controller circuit is a simple mechanism to detect and control the level of water in the overhead tank and also in the other containers. Nowadays, all the householders/owners are storing the water in overhead tanks by using the pumps. When the water is stored in the tank, no one can identify the level of water and also, no one can know when the water tank will fill. Hence there is an overflow of water in the tank, thus there is a waste of energy and water.

To Resolve this type of problems by using the water level Controller circuit using BC547 transistor it helps and control the overflow level of water. The cost of the water level controller manufacturing cost is low and its full use for the overhead water tanks, swimming pool boilers, etc.. The water level controller circuits are used in the factories, chemical plants, and electrical substations and also in other liquid storage systems.

This simple transistor based water level controller circuit is very useful to indicate the water levels in a tank. Whenever tank gets filled, the motor Switches off. Here we have created 3 levels (Main, Low, High), we can create alarms and LED for more levels as we need. When tanks get filled completely the motor will Turn Off. We guys are Ankit Gupta R, Bala Murugan N G and Mohammed Jaffer M made this project.

Use this type for sensor wiring connections. In SPDT relay we are having 5 terminals Com(Movable Contact), Coil terminals, NO and NC

NO= Normally Opened

If your Motor Positive end is connected to NO. When the relay is switched, the motor will turn ON. Otherwise it is in OFF state.

NC=Normally Closed

If your Motor Positive end is connected to NC. When the relay is switched, the motor will turn OFF. Otherwise it is in ON state.

In the COM port we must add the external power supply to drive the motor. The coil terminals are only for Switching the relay from NC to NO. The relays are of different types here am using 12v DC SPDT Relay.

BC 547 transistors are very negligible so handle the transistor carefully and don't change the polarity of the battery terminal to the circuit.

Here I used 12v Submergible motor for my purpose so I Designed 12v DC power supply connect to both circuit and Com Port of the Relay. We can also give 5v for the circuit if you are using 5v Relay.If you need your circuit for 230v motor control operation, you just connect the 230v positive terminal to Com port of Relay and the negative terminal connect to motor another end(-) Gnd. No need to change any components.

Finally we Designed the circuit and make sure that your circuit should be tested in Breadboard after that you can go for the Soldering in PCB or Dot Board. We can also use IC555 timer for the automatic water level controller to get the output in an effective manner because transistors may burst any time. See you next time to my Next Project. If you have any queries kindly ask in the comments, we will clarify you at any time.

Ne555 automatic water pump control circuit

Hii Everyone here we are going to learn about saving the water efficiently. So go through the steps and the Sentences carefully. Water tank overflow is a common problem which leads to the wastage of water. Although there are many solutions to it like ball valves which automatically stop the water flow once the tank gets full. The water level controller circuit is a simple mechanism to detect and control the level of water in the overhead tank and also in the other containers. Nowadays, all the householders/owners are storing the water in overhead tanks by using the pumps. When the water is stored in the tank, no one can identify the level of water and also, no one can know when the water tank will fill. Hence there is an overflow of water in the tank, thus there is a waste of energy and water.

To Resolve this type of problems by using the water level Controller circuit using BC547 transistor it helps and control the overflow level of water. The cost of the water level controller manufacturing cost is low and its full use for the overhead water tanks, swimming pool boilers, etc.. The water level controller circuits are used in the factories, chemical plants, and electrical substations and also in other liquid storage systems.

This simple transistor based water level controller circuit is very useful to indicate the water levels in a tank. Whenever tank gets filled, the motor Switches off. Here we have created 3 levels (Main, Low, High), we can create alarms and LED for more levels as we need. When tanks get filled completely the motor will Turn Off. We guys are Ankit Gupta R, Bala Murugan N G and Mohammed Jaffer M made this project.

Use this type for sensor wiring connections. In SPDT relay we are having 5 terminals Com(Movable Contact), Coil terminals, NO and NC

NO= Normally Opened

If your Motor Positive end is connected to NO. When the relay is switched, the motor will turn ON. Otherwise it is in OFF state.

NC=Normally Closed

If your Motor Positive end is connected to NC. When the relay is switched, the motor will turn OFF. Otherwise it is in ON state.

In the COM port we must add the external power supply to drive the motor. The coil terminals are only for Switching the relay from NC to NO. The relays are of different types here am using 12v DC SPDT Relay.

BC 547 transistors are very negligible so handle the transistor carefully and don't change the polarity of the battery terminal to the circuit.

Here I used 12v Submergible motor for my purpose so I Designed 12v DC power supply connect to both circuit and Com Port of the Relay. We can also give 5v for the circuit if you are using 5v Relay.If you need your circuit for 230v motor control operation, you just connect the 230v positive terminal to Com port of Relay and the negative terminal connect to motor another end(-) Gnd. No need to change any components.

Finally we Designed the circuit and make sure that your circuit should be tested in Breadboard after that you can go for the Soldering in PCB or Dot Board. We can also use IC555 timer for the automatic water level controller to get the output in an effective manner because transistors may burst any time. See you next time to my Next Project. If you have any queries kindly ask in the comments, we will clarify you at any time.

No comments:

Post a Comment