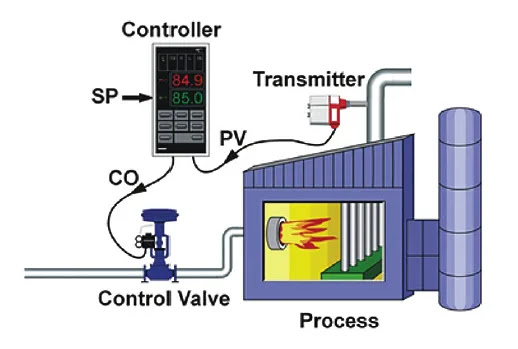

Examine these pressure and level control loops (transmitter-controller-valve systems) for an industrial boiler, controlling both water level and steam pressure:

If the PIC setpoint is 225 PSI and the measured steam pressure begins to rise above that value, how should the PIC respond, and how will this response bring the steam pressure back down to setpoint?

Describe a situation where the block and bypass hand valves installed on the fuel gas line might ever be used, either by operations or by maintenance personnel.

If the I/P transducer on the level control loop suddenly fell out of calibration in such a way that it outputs a pneumatic signal that was too low, how would this affect the control of water level in the steam drum?

If steam pressure begins to fall below setpoint, the PIC should send a decreasing signal to the fuel gas valve, causing the burner to produce less heat and thereby lowering the steam pressure to setpoint again. If well-tuned, a loop controller will drive its output signal to whatever value is necessary to achieve PV = SP.

The manual block and bypass valves are useful for taking the fuel control valve out of service while the boiler is still running. This allows technicians to stroke-test and even replace the control valve without shutting down the boiler. I will let you describe and explain the sequence of valve motions necessary to take a working control valve out of service. (use comments section to share your way of doing it.)

A falsely low pressure signal coming from the I/P might cause the actual water level to drop if the change was sudden, but the LIC will eventually compensate for this change by adjusting its output signal value until the control valve is at the correct position. again.

Explain what would happen to this process if the air supply to the feedwater valve's I/P transducer failed.

Explain what would happen to this process if the air supply to the fuel valve's I/P transducer failed.

Explain how both control loops will respond to a sudden increase in steam demand

Examine these pressure and level control loops (transmitter-controller-valve systems) for an industrial boiler, controlling both water level and steam pressure:

If the PIC setpoint is 225 PSI and the measured steam pressure begins to rise above that value, how should the PIC respond, and how will this response bring the steam pressure back down to setpoint?

Describe a situation where the block and bypass hand valves installed on the fuel gas line might ever be used, either by operations or by maintenance personnel.

If the I/P transducer on the level control loop suddenly fell out of calibration in such a way that it outputs a pneumatic signal that was too low, how would this affect the control of water level in the steam drum?

If steam pressure begins to fall below setpoint, the PIC should send a decreasing signal to the fuel gas valve, causing the burner to produce less heat and thereby lowering the steam pressure to setpoint again. If well-tuned, a loop controller will drive its output signal to whatever value is necessary to achieve PV = SP.

The manual block and bypass valves are useful for taking the fuel control valve out of service while the boiler is still running. This allows technicians to stroke-test and even replace the control valve without shutting down the boiler. I will let you describe and explain the sequence of valve motions necessary to take a working control valve out of service. (use comments section to share your way of doing it.)

A falsely low pressure signal coming from the I/P might cause the actual water level to drop if the change was sudden, but the LIC will eventually compensate for this change by adjusting its output signal value until the control valve is at the correct position. again.

Explain what would happen to this process if the air supply to the feedwater valve's I/P transducer failed.

Explain what would happen to this process if the air supply to the fuel valve's I/P transducer failed.

Explain how both control loops will respond to a sudden increase in steam demand

No comments:

Post a Comment