Understanding hydraulic jacks

Ever since the invention of jacks, their applications extensively serve a great purpose in different fields for lifting great forces or lift heavy loads. There are different types of jacks out there, although they perform the same operation. The most commonly used and available ones are mechanical jack and hydraulic jacks. Mechanical jack work with screw thread for lifting heavy equipment, while hydraulic jack uses hydraulic power. This jack is often used in the automotive industry.

Today you’ll get to know the definition, applications, components, diagram, types, working, advantages, and disadvantages of hydraulic jacks.

What is a hydraulic jack?

Hydraulic jacks are mechanical devices used to lift heavyweight. They are commonly used in automobile industries to lift vehicles from the ground, which is why they are known as a kind of hydraulic car jack. Normally, jacks are rated for a maximum lifting capacity, for example, 1.5 tons or 3 tons. Industrial jacks can be rated for many tons of load.

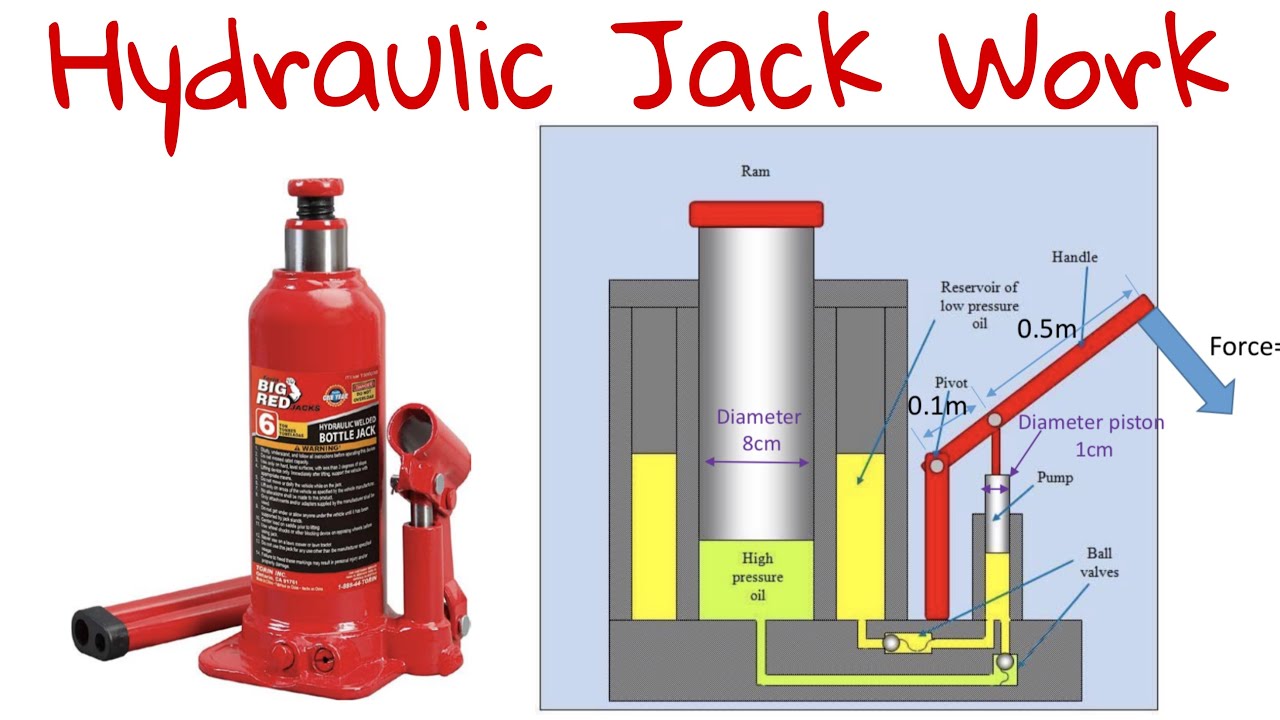

The force of hydraulic jacks can be calculated with pascal’s law. Hydraulic jacks consist of two pistons inside the cylinder that is responsible for lifting the heavyweight. The bigger and smaller cylinder are connected together. The small piston forces the fluid to lift the big piston. There are two ball valves that work as a check valve, allowing flow and stop the flow while pumping.

A bar is inserted into the handle socket of the jack, when pumped, the hydraulic fluid forces by a piston and go through a one-way valve. The fluid force acts at the bottom of the bigger cylinder, allowing the ram to go upwards. The other valve is blocked so pressurized fluid can’t back until it is unscrewed. This is how the hydraulic jack works.

Applications of hydraulic jacks

Jacks as a whole have wide applications in different industries and are used to lift and transport heavy loads, relieve vertical forces from weight-bearing members to create space for repairs. Hydraulic jacks or other kinds are also equipment used in construction work, shipbuilding, automotive repair, and other specialized industries. Below are the applications of all types of jacks including hydraulic jacks.

Components of hydraulic jacks

To illustrate and understand the components of hydraulic jacks, a typical manually operated hydraulic jack will be considered since it’s commonly used. Below are the major components of hydraulic jacks.

A reservoir or buffer tank – is a vessel that holds the hydraulic fluid or pumps oil which will be used to transfer applied pressure from the pump to the ram.

Piston pump – is a part that is mechanically activated by moving the pump lever or handle up and down.

Pump lever or handle – the movement of the pump lever builds up pressure in the hydraulic fluid which transfers that pressurized fluid through a check valve and into the main cylinder.

The main cylinder – is also referred to as ram, when drive upwards, it extends out of the hydraulic jack body by the pressure of the hydraulic fluid, creating the required lifting force and lifting the load.

Release valve – is a part that helps to release the pressure so that the ram can retract and the load can be lowered.

Bottle jacks are also known as hand jacks, they became popular in the early 1900s when the automobile industry began to take off. They are portable and they serve a great purpose for individuals to lift a vehicle for roadside inspection or service. It is named bottle jack because it’s designed in the shape of a milk bottle. Today’s bottle jacks have the capability of lifting from one hundred pounds to several tons, although they range in size.

Unlike bottle jack shafts which are operated vertically, floor jacks are horizontally operated. The shaft pushes on a crank that connects to a lifting pad, which is then lifted vertically. These types of hydraulic jacks provide a greater range of vertical lift than bottle jacks and are available in two sizes. The conventional size is about four feet long, a foot wide, and weighs around 200 pounds. They can lift about 4 – 10 tons. A more compact model was later made, it can lift 11/12 tons, it’s about three feet in length. Also, there are mini-jacks but are not recognized as standard types of a floor jack. Note: hydraulic jacks are designed to be operated by hand power air (compressed), electric, or gas.

Toe lift hydraulic jacks:

The toe lift hydraulic jacks are special types used to lift machinery and other loads that have low clearance between the ground and the bottom surface of the load. This special jack works in situations where the bottle jack or floor jack can’t work due to the low ground clearance of the load.

Scissor jacks are compact jacks that use a mechanical screw. The screw rotation results in the raising and lowering of a set of scissoring arms that extend or retract depending on the position of the screw mechanism.

Screw jacks are mechanical jacks that use a vertical screw mechanism to lift and lower the load. Some are designed to be wrench adjustable while others make use of a level inserted through a hole in the jack. This allows additional mechanical advantage to using when turning the screw lift the load.

Understanding hydraulic jacks

Ever since the invention of jacks, their applications extensively serve a great purpose in different fields for lifting great forces or lift heavy loads. There are different types of jacks out there, although they perform the same operation. The most commonly used and available ones are mechanical jack and hydraulic jacks. Mechanical jack work with screw thread for lifting heavy equipment, while hydraulic jack uses hydraulic power. This jack is often used in the automotive industry.

Today you’ll get to know the definition, applications, components, diagram, types, working, advantages, and disadvantages of hydraulic jacks.

What is a hydraulic jack?

Hydraulic jacks are mechanical devices used to lift heavyweight. They are commonly used in automobile industries to lift vehicles from the ground, which is why they are known as a kind of hydraulic car jack. Normally, jacks are rated for a maximum lifting capacity, for example, 1.5 tons or 3 tons. Industrial jacks can be rated for many tons of load.

The force of hydraulic jacks can be calculated with pascal’s law. Hydraulic jacks consist of two pistons inside the cylinder that is responsible for lifting the heavyweight. The bigger and smaller cylinder are connected together. The small piston forces the fluid to lift the big piston. There are two ball valves that work as a check valve, allowing flow and stop the flow while pumping.

A bar is inserted into the handle socket of the jack, when pumped, the hydraulic fluid forces by a piston and go through a one-way valve. The fluid force acts at the bottom of the bigger cylinder, allowing the ram to go upwards. The other valve is blocked so pressurized fluid can’t back until it is unscrewed. This is how the hydraulic jack works.

Applications of hydraulic jacks

Jacks as a whole have wide applications in different industries and are used to lift and transport heavy loads, relieve vertical forces from weight-bearing members to create space for repairs. Hydraulic jacks or other kinds are also equipment used in construction work, shipbuilding, automotive repair, and other specialized industries. Below are the applications of all types of jacks including hydraulic jacks.

Components of hydraulic jacks

To illustrate and understand the components of hydraulic jacks, a typical manually operated hydraulic jack will be considered since it’s commonly used. Below are the major components of hydraulic jacks.

A reservoir or buffer tank – is a vessel that holds the hydraulic fluid or pumps oil which will be used to transfer applied pressure from the pump to the ram.

Piston pump – is a part that is mechanically activated by moving the pump lever or handle up and down.

Pump lever or handle – the movement of the pump lever builds up pressure in the hydraulic fluid which transfers that pressurized fluid through a check valve and into the main cylinder.

The main cylinder – is also referred to as ram, when drive upwards, it extends out of the hydraulic jack body by the pressure of the hydraulic fluid, creating the required lifting force and lifting the load.

Release valve – is a part that helps to release the pressure so that the ram can retract and the load can be lowered.

Bottle jacks are also known as hand jacks, they became popular in the early 1900s when the automobile industry began to take off. They are portable and they serve a great purpose for individuals to lift a vehicle for roadside inspection or service. It is named bottle jack because it’s designed in the shape of a milk bottle. Today’s bottle jacks have the capability of lifting from one hundred pounds to several tons, although they range in size.

Unlike bottle jack shafts which are operated vertically, floor jacks are horizontally operated. The shaft pushes on a crank that connects to a lifting pad, which is then lifted vertically. These types of hydraulic jacks provide a greater range of vertical lift than bottle jacks and are available in two sizes. The conventional size is about four feet long, a foot wide, and weighs around 200 pounds. They can lift about 4 – 10 tons. A more compact model was later made, it can lift 11/12 tons, it’s about three feet in length. Also, there are mini-jacks but are not recognized as standard types of a floor jack. Note: hydraulic jacks are designed to be operated by hand power air (compressed), electric, or gas.

Toe lift hydraulic jacks:

The toe lift hydraulic jacks are special types used to lift machinery and other loads that have low clearance between the ground and the bottom surface of the load. This special jack works in situations where the bottle jack or floor jack can’t work due to the low ground clearance of the load.

Scissor jacks are compact jacks that use a mechanical screw. The screw rotation results in the raising and lowering of a set of scissoring arms that extend or retract depending on the position of the screw mechanism.

Screw jacks are mechanical jacks that use a vertical screw mechanism to lift and lower the load. Some are designed to be wrench adjustable while others make use of a level inserted through a hole in the jack. This allows additional mechanical advantage to using when turning the screw lift the load.

No comments:

Post a Comment