What is Suspension?

Suspension System Types & Components :- The suspension system of a vehicle isolates the wheel section from the body. All the power that is generated from the engine is finally transmitted to the wheel through the power transmission system. With this power, the vehicle moves on the road. The irregular roads cause shocks on the wheels and at this point the suspension system acts more like a filter to screen out the vehicle. The main function of the suspension system is to separate the vehicle body or frame from shocks and vibrations due to bad driving.

Good Suspension System

A good suspension system is one that absorbs all shocks and vibrations due to bad driving conditions and transmits as small a component of shocks and vibrations as possible to the passenger carriage. Springiness is elastic resistance to a load. On application of a sudden load, the spring system will be compressed or expanded as the case may be without transmitting the same to the body. As the spring compresses it absorbs energy and dissipates in the form of heat energy and when it expands it rebounds.

Hence the main objective of a good suspension system is to separate the structure, as much as possible, from shock loading and vibrations due to the irregularities of the road surface. This is achieved by flexible elements like springs and dampers. Another function of the suspension system is to achieve the main function without compromising the stability, steering, or general handling qualities of the vehicle. This is done by controlling, by the use of mechanical connections.

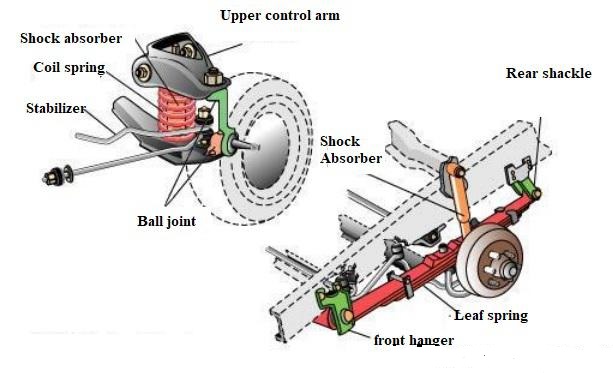

Components of Suspension System

Knuckle or Upright

Linkages

Wheels/tyres

Dampers/Shock Absorbers

Springs

Struts

Anti Sway Bars

Ball joints

Spindle

1. Knuckle or Upright:

This is used to connect the wheels to the suspension system. It is mounted on the wheel's hub. The suspension system is connected together with the linkages provided. The knuckle is having a caster angle and a king-pin on the front wheels which helps in steering of the vehicle in left or right direction.

2. Linkages:

Linkages are like frame of suspension system. All the parts of suspension system are connected together with the help of linkages. These links have universal joints on both ends which help in smooth connection between different components.

Generally there are 3 types of linkages present in the suspension system which are as follows:

A) Wishbones or A-arm

It is a solid linkage which connects the frame of the body and the wheel hub. It is in the shape of alphabet A. The top end of A arm is attached to a knuckle which is mounted on a wheel hub and the rest of the two ends are attached to the frame of the body. Depending on the requirement double A-arm can be used.

B) Solid axle or live axle

It is the main axle of the tires. It connects the main body of the vehicle with a knuckle of the tire. Whole weight of the body lies on this solid axle. The suspension system is mounted on this axle between the body and the axle. This is commonly used in heavy duty vehicles.

C) multiple links

This is the most commonly used in cars. In this multiple small linkages are used in place of wishbone arm and solid axle. By the help of these multiple links knuckle, frame and suspension system are connected together.

3. Wheels/Tires:

Wheel or tires are those components of the suspension system which comes into contact with the actual irregularities of the road. Wheels are the main components of the automobile as well because they are eventually responsible for the motion of the automobile. When wheels come across surface irregularities of road they move up and down. This up and down motion causes the actual vibration in the body. To eliminate these vibrations, the suspension system is placed between the body and the wheels. The suspension system absorbs vibrations and helps in a comfortable ride.

4. Dampers/Shock Absorbers:

Shock Absorber :- Dampers are used to absorb the vibration and dissipate it in the form of heat energy. In damping action energy is converted from one form or the other. In old days, the friction effect between two surfaces is used as a damping agent. Semi rotary vane-type dampers were also used. However, they were abandoned because the ratio of sealing length around their vans to the volume displaced was so high that these units were rapidly adversely affected by wear.

In modern cars mostly following two types of hydraulic dampers are used:

• Telescopic dampers

• Rocking lever dampers.

1. Telescopic Damper

Telescopic dampers are quite often incorrectly called shock absorbers. In telescopic dampers, the piston-cylinder arrangement is there. In this system, hydraulic fluid flows past the pistons and fluid absorbs the shocks and vibrations.

2. Rocking lever damper

Rocking lever dampers work on the same principle as telescopic dampers. But in this case, aTwo-piston is used inside the single-cylinder, and oil is displaced through the valve. The movement of the dual pistons takes place due to the movement of the wheels which is moved onto the pistons into the rocker levers.

5. Spring:

Springs act as reservoirs of energy. Springs store the energy when impact force which acts when the vehicle passes over irregularities of the road. It compresses the spring. This energy is released when spring expands subsequently and with the help of dampers, thus the energy is converted into heat and the shocks and bounce are absorbed.

When the vehicle hits a bump, the tire is suddenly pushed up. In the case of rigid suspension, the full force will be transferred to the carriage unit and pushed up with almost no loss of force in the form of a jerk or bounce. However, when a spring is present, the force acting on the vehicle compresses the spring which absorbs the shock and avoids this from being transferred to the vehicle frame.

The important factors which govern the choice of which types of springs are used are:

• Overall cost of installation.

• Relative capacity for storing energy.

• Total weight of suspension system.

Fatigue life.

Location

The major types of springs that are used are:

• Leaf springs or laminated springs

Coil springs

Torsion bars

1. Leaf Springs

Leaf springs are also known as laminated springs because they are basically steel strips that are mounted over one another or laminated with a constant reduction in length. They are also called semi-elliptical springs as they are bent in that form. However, nowadays they are almost straight.

2. Coil Springs

The coil shape is the best energy-storing shape for the given weight and a coil spring stores the energy when force is acted on it twists and stores the torsional energy. Coil springs have the benefit of fitting in a compact area. The life of coil springs is increased by shot peening, which increases and reduces their compressive strength, and also increases scratch resistance. The life of the coil spring also depends on the diameter of the wire used and the diameter of the coil shape. The material used also plays an important role in the life of the coil spring.

3. Torsion bars

In the case of torsion bars, a steel bar is used. The steel bars act like spring. It is fixed at one end to the body and with the help of a lever; the movement of the wheel or axle is transferred to the torsion bar in form of torque. As a result, the torsion bar twists and deformation takes place and shear stress is induced. The material properties are responsible to regain the bar's original shape (i.e. untwisted) hence when the force acts on the torsion bar it twists and untwists which creates a spring effect.

Torsion bars are the bar's shape structure which is overloaded in torsion during manufacture—to stretch outer layers beyond the elastic limit. As this leaves remaining stress in the external layers, the highest stress under service occurs beneath the surface where it is less likely to begin cracks. This helps to increase the fatigue life. Shot peening is also provided in torsion bars as in coil spring case to increase fatigue life.

6. Strut:

Strut is a major component of the suspension system. It is used in MacPherson strut assembly. Strut is basically the combination of spring and damper which is having two ends which will be attached to the frame and the wheel. Spring is used to store kinetic energy into potential energy and damper dissipates the kinetic energy into heat energy. Both these components work together to form a strut assembly. The size of the spring used in strut depends upon the load capacity of the vehicle.

7. Anti Sway Bars:

These are also known as anti-roll bars. Anti sway bars play a key role in passenger comfort and vehicle stability to improve vehicle performance. Anti sway bars act as one of the key components in a vehicle suspension system. As the name suggests their purpose is to reduce body roll or sway when operating under cornering conditions.

8. Ball joints:

Ball joints are the critical components of the suspension system. It helps to connect different parts and linkages and allow them to move relative to other linkages. Ball joints consist of a metal housing and stud. The stud is able to swing and rotate within the housing. The grease lubrication is also provided in the socket of ball joint. Inside the housing bearings are provided which can be of metal or plastic. Two ends of ball joints are connected to housing and stud respectively.

9. Spindle:

Spindle enables to drive forward, backward, turn in both directions and brake. The basic function of a spindle is to allow an axle to rotate. The spindle also helps the vehicle to move in straight line by gearing which is called a castor. The castor is basically a forward and backward inclination that regulates the steering process

What is Suspension?

Suspension System Types & Components :- The suspension system of a vehicle isolates the wheel section from the body. All the power that is generated from the engine is finally transmitted to the wheel through the power transmission system. With this power, the vehicle moves on the road. The irregular roads cause shocks on the wheels and at this point the suspension system acts more like a filter to screen out the vehicle. The main function of the suspension system is to separate the vehicle body or frame from shocks and vibrations due to bad driving.

Good Suspension System

A good suspension system is one that absorbs all shocks and vibrations due to bad driving conditions and transmits as small a component of shocks and vibrations as possible to the passenger carriage. Springiness is elastic resistance to a load. On application of a sudden load, the spring system will be compressed or expanded as the case may be without transmitting the same to the body. As the spring compresses it absorbs energy and dissipates in the form of heat energy and when it expands it rebounds.

Hence the main objective of a good suspension system is to separate the structure, as much as possible, from shock loading and vibrations due to the irregularities of the road surface. This is achieved by flexible elements like springs and dampers. Another function of the suspension system is to achieve the main function without compromising the stability, steering, or general handling qualities of the vehicle. This is done by controlling, by the use of mechanical connections.

Components of Suspension System

Knuckle or Upright

Linkages

Wheels/tyres

Dampers/Shock Absorbers

Springs

Struts

Anti Sway Bars

Ball joints

Spindle

1. Knuckle or Upright:

This is used to connect the wheels to the suspension system. It is mounted on the wheel's hub. The suspension system is connected together with the linkages provided. The knuckle is having a caster angle and a king-pin on the front wheels which helps in steering of the vehicle in left or right direction.

2. Linkages:

Linkages are like frame of suspension system. All the parts of suspension system are connected together with the help of linkages. These links have universal joints on both ends which help in smooth connection between different components.

Generally there are 3 types of linkages present in the suspension system which are as follows:

A) Wishbones or A-arm

It is a solid linkage which connects the frame of the body and the wheel hub. It is in the shape of alphabet A. The top end of A arm is attached to a knuckle which is mounted on a wheel hub and the rest of the two ends are attached to the frame of the body. Depending on the requirement double A-arm can be used.

B) Solid axle or live axle

It is the main axle of the tires. It connects the main body of the vehicle with a knuckle of the tire. Whole weight of the body lies on this solid axle. The suspension system is mounted on this axle between the body and the axle. This is commonly used in heavy duty vehicles.

C) multiple links

This is the most commonly used in cars. In this multiple small linkages are used in place of wishbone arm and solid axle. By the help of these multiple links knuckle, frame and suspension system are connected together.

3. Wheels/Tires:

Wheel or tires are those components of the suspension system which comes into contact with the actual irregularities of the road. Wheels are the main components of the automobile as well because they are eventually responsible for the motion of the automobile. When wheels come across surface irregularities of road they move up and down. This up and down motion causes the actual vibration in the body. To eliminate these vibrations, the suspension system is placed between the body and the wheels. The suspension system absorbs vibrations and helps in a comfortable ride.

4. Dampers/Shock Absorbers:

Shock Absorber :- Dampers are used to absorb the vibration and dissipate it in the form of heat energy. In damping action energy is converted from one form or the other. In old days, the friction effect between two surfaces is used as a damping agent. Semi rotary vane-type dampers were also used. However, they were abandoned because the ratio of sealing length around their vans to the volume displaced was so high that these units were rapidly adversely affected by wear.

In modern cars mostly following two types of hydraulic dampers are used:

• Telescopic dampers

• Rocking lever dampers.

1. Telescopic Damper

Telescopic dampers are quite often incorrectly called shock absorbers. In telescopic dampers, the piston-cylinder arrangement is there. In this system, hydraulic fluid flows past the pistons and fluid absorbs the shocks and vibrations.

2. Rocking lever damper

Rocking lever dampers work on the same principle as telescopic dampers. But in this case, aTwo-piston is used inside the single-cylinder, and oil is displaced through the valve. The movement of the dual pistons takes place due to the movement of the wheels which is moved onto the pistons into the rocker levers.

5. Spring:

Springs act as reservoirs of energy. Springs store the energy when impact force which acts when the vehicle passes over irregularities of the road. It compresses the spring. This energy is released when spring expands subsequently and with the help of dampers, thus the energy is converted into heat and the shocks and bounce are absorbed.

When the vehicle hits a bump, the tire is suddenly pushed up. In the case of rigid suspension, the full force will be transferred to the carriage unit and pushed up with almost no loss of force in the form of a jerk or bounce. However, when a spring is present, the force acting on the vehicle compresses the spring which absorbs the shock and avoids this from being transferred to the vehicle frame.

The important factors which govern the choice of which types of springs are used are:

• Overall cost of installation.

• Relative capacity for storing energy.

• Total weight of suspension system.

Fatigue life.

Location

The major types of springs that are used are:

• Leaf springs or laminated springs

Coil springs

Torsion bars

1. Leaf Springs

Leaf springs are also known as laminated springs because they are basically steel strips that are mounted over one another or laminated with a constant reduction in length. They are also called semi-elliptical springs as they are bent in that form. However, nowadays they are almost straight.

2. Coil Springs

The coil shape is the best energy-storing shape for the given weight and a coil spring stores the energy when force is acted on it twists and stores the torsional energy. Coil springs have the benefit of fitting in a compact area. The life of coil springs is increased by shot peening, which increases and reduces their compressive strength, and also increases scratch resistance. The life of the coil spring also depends on the diameter of the wire used and the diameter of the coil shape. The material used also plays an important role in the life of the coil spring.

3. Torsion bars

In the case of torsion bars, a steel bar is used. The steel bars act like spring. It is fixed at one end to the body and with the help of a lever; the movement of the wheel or axle is transferred to the torsion bar in form of torque. As a result, the torsion bar twists and deformation takes place and shear stress is induced. The material properties are responsible to regain the bar's original shape (i.e. untwisted) hence when the force acts on the torsion bar it twists and untwists which creates a spring effect.

Torsion bars are the bar's shape structure which is overloaded in torsion during manufacture—to stretch outer layers beyond the elastic limit. As this leaves remaining stress in the external layers, the highest stress under service occurs beneath the surface where it is less likely to begin cracks. This helps to increase the fatigue life. Shot peening is also provided in torsion bars as in coil spring case to increase fatigue life.

6. Strut:

Strut is a major component of the suspension system. It is used in MacPherson strut assembly. Strut is basically the combination of spring and damper which is having two ends which will be attached to the frame and the wheel. Spring is used to store kinetic energy into potential energy and damper dissipates the kinetic energy into heat energy. Both these components work together to form a strut assembly. The size of the spring used in strut depends upon the load capacity of the vehicle.

7. Anti Sway Bars:

These are also known as anti-roll bars. Anti sway bars play a key role in passenger comfort and vehicle stability to improve vehicle performance. Anti sway bars act as one of the key components in a vehicle suspension system. As the name suggests their purpose is to reduce body roll or sway when operating under cornering conditions.

8. Ball joints:

Ball joints are the critical components of the suspension system. It helps to connect different parts and linkages and allow them to move relative to other linkages. Ball joints consist of a metal housing and stud. The stud is able to swing and rotate within the housing. The grease lubrication is also provided in the socket of ball joint. Inside the housing bearings are provided which can be of metal or plastic. Two ends of ball joints are connected to housing and stud respectively.

9. Spindle:

Spindle enables to drive forward, backward, turn in both directions and brake. The basic function of a spindle is to allow an axle to rotate. The spindle also helps the vehicle to move in straight line by gearing which is called a castor. The castor is basically a forward and backward inclination that regulates the steering process

No comments:

Post a Comment