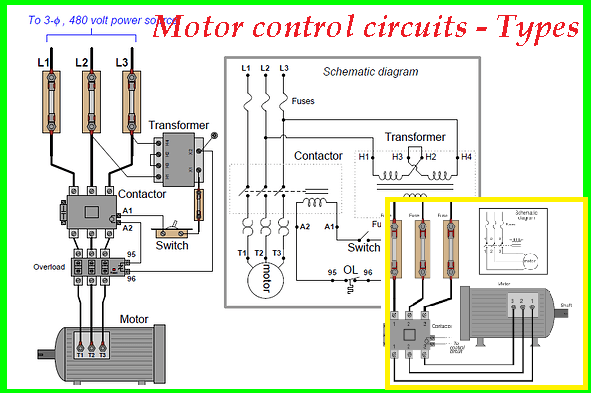

Motor control circuits - Types

The function of the motor control circuit is to control the AC motors 46. A higher voltage is required to start the motor, where a voltage lower than the starting voltage is required to operate. Changing the motor from a higher voltage to a lower voltage is the main function of a motor control circuit.

There are mainly there are three types of motor control circuits:

Direct On Line Starter (DOL starter)

Star Delta Starter

Auto Transformer Starter

Direct Online Starter (DOL) are used in small motors with has lower power under 10kW.

.

In overcurrent protection circuits, fuses and circuit breakers are commonly used. Fuses and circuit breakers are configured to interrupt the connection if the current in the line exceeds the rated motor current.

Star Delta Starter:

To decrease the starting current cage motors of medium and larger sizes are started at a reduced supply voltage. The reduced supply voltage starting is applied in the Star Delta methods. This is applicable to motors designed for delta connection in normal running conditions.

.

Both ends of each phase of the stator winding are brought out as six terminals. For starting, the stator windings are connected in star and when the machine is running the switch is thrown quickly to the running position by automatically.

When the motor is started in the star connection, the phase voltage of the motor is reduced by a factor of √3. The starting line current of the motor will be reduced to a 1/3 value of DOL Delta starting.

Auto Transformer starter:

This assembly consisting of contactor, overload block, control power transformer, power fuses. the initial voltage applied to the motor and therefore the starting current and torque. The motor, which can be connected permanently in delta or in a star, is switched first on a reduced voltage from a 3-phase tapped autotransformer and when it has accelerated sufficiently, it is switched to the running (full voltage) position.

.

This method is more expensive because of the additional autotransformer and uses this starter for motors above 80kW.

Initially, a high voltage is given to the contactor coil, then overload (“OL”) contact wired in series with the contactor coil so that a thermal overload event forces the contactor to de-energize and thus interrupt power to the motor even if the control switch is still in the “on” position.

In this control system, firstly star contactor will be energized. Soon after the transformer contactor will be energized. Then after a time delay while the main contactor is energized the star contactor will be energized. At this moment, motor has got the full load. Then after a time delay, transformer contactor also will be de-energized.

Motor control circuits - Types

The function of the motor control circuit is to control the AC motors 46. A higher voltage is required to start the motor, where a voltage lower than the starting voltage is required to operate. Changing the motor from a higher voltage to a lower voltage is the main function of a motor control circuit.

There are mainly there are three types of motor control circuits:

Direct On Line Starter (DOL starter)

Star Delta Starter

Auto Transformer Starter

Direct Online Starter (DOL) are used in small motors with has lower power under 10kW.

.

In overcurrent protection circuits, fuses and circuit breakers are commonly used. Fuses and circuit breakers are configured to interrupt the connection if the current in the line exceeds the rated motor current.

Star Delta Starter:

To decrease the starting current cage motors of medium and larger sizes are started at a reduced supply voltage. The reduced supply voltage starting is applied in the Star Delta methods. This is applicable to motors designed for delta connection in normal running conditions.

.

Both ends of each phase of the stator winding are brought out as six terminals. For starting, the stator windings are connected in star and when the machine is running the switch is thrown quickly to the running position by automatically.

When the motor is started in the star connection, the phase voltage of the motor is reduced by a factor of √3. The starting line current of the motor will be reduced to a 1/3 value of DOL Delta starting.

Auto Transformer starter:

This assembly consisting of contactor, overload block, control power transformer, power fuses. the initial voltage applied to the motor and therefore the starting current and torque. The motor, which can be connected permanently in delta or in a star, is switched first on a reduced voltage from a 3-phase tapped autotransformer and when it has accelerated sufficiently, it is switched to the running (full voltage) position.

.

This method is more expensive because of the additional autotransformer and uses this starter for motors above 80kW.

Initially, a high voltage is given to the contactor coil, then overload (“OL”) contact wired in series with the contactor coil so that a thermal overload event forces the contactor to de-energize and thus interrupt power to the motor even if the control switch is still in the “on” position.

In this control system, firstly star contactor will be energized. Soon after the transformer contactor will be energized. Then after a time delay while the main contactor is energized the star contactor will be energized. At this moment, motor has got the full load. Then after a time delay, transformer contactor also will be de-energized.

No comments:

Post a Comment